Properties of Lubricants:-

Lubricants have several properties, some important properties are

given below:-

1.

Viscosity:

It is the property of a liquid or a fluid by virtue of which it offers

resistance to its own flow. If two layers of a liquid separated by a distance’s

and moving with a relative velocity difference ‘v’ then force per unit area(f)

required to maintain this velocity difference is given by-

f=nv/d

Where

n is the coefficient of viscosity.Viscosity

is the most important property of any lubricating oil. If the viscosity of the

oil is too low a liquid oil film cannot be maintained between two moving

surfaces and excessive wearing takes place.

Determination of Viscosity:

The

apparatus which is used to determine the viscosity is known as viscometer. In

industry viscosity of lubricating oil is determined by Redwood, say bolt and

Angler instrument. In the Redwood viscometer the measure of viscosity of oil is

the time in seconds for 0ml of oil to flow through standard orifice under a

given set of condition.

By

Redwood Viscometer: It is of two

types:- (i). Rw1 , (ii).Rw2

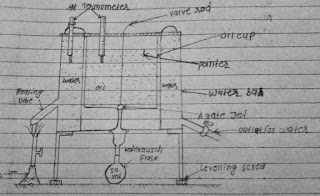

Fig.1.(a). Redwood viscometer no. 1

Working:

The

apparatus is leveled and water bath is filled with water. A thermometer is

placed in water bath. The oil cup is cleaned and ball of value rod is places on

the agate jet to close it. An empty cleaned kohlrausch flask is kept just below

the jet. The experimental oil is listed in oil cup up to a pointer. A

thermometer is also placed in oil cup read the temperature of oil. Now water

bath is heated up to a certain temperature with constant stirring the water.

When the oil at desired temperature heating is stopped and the ball valve is

fitted and suspended from thermometer bracket. The time taken for 50ml of the

oil to pass through the agate jet and collected into kohlrausch mask is noted.

Now the valve immediately closed to prevent any overflow of the oil. The

experiment is repeated and the mean value of time of flow for 50ml oil sample

is reported as a result expressed in “Redwood No. 1 seconds” at a particular

temperature then

n1/n2 =r1t1/r2t2

where

n1= viscosity of experimental oil sample

n2=

viscosity of standard liquid

r1=

Density of experimental liquid

t1=

Time of flow of experimental oil sample

Thus

the value of n1 i.e., viscosity of experimental oil is calculated in

‘poise’.

2.

Viscosity

Index:-

The

arbitrary scale which measures the variation of viscosity with temperature is

called viscosity index. Generally the viscosity of an oil decreases with rise

in temperature. The viscosity of a good lubricant should not change very much

with the rise in temperature. If the viscosity of oil is very much affected

with the rise in temperature it is called low viscosity index. Similarly if the

viscosity of oil is slightly affected with the rise in temperature, it is

called high viscosity index lubricant. A good lubricant should have high

viscosity index.

Determination of Viscosity

index:

For

the determination of viscosity index of experimental oil the viscosities of

testing oil at 100ºf

and 210ºf

are found out. The viscosity at 100ºf

of the oil under test is represented by ‘U’. Now we compare the viscosity of

oil under test with two standard oil, one with the highest viscosity index

(VI=100) and another with the lower viscosity index(VI=0). Pennsylvanian oils

have highest viscosity index(VI=100) and Gulf oil have lowest viscosity index(VI=0). Now viscosity index (VI) may be

calculated as:-

Viscosity

Index(VI)= L-U/L-H*100

Where

‘U’ is the viscosity of experimental oil at 100ºf.

And ‘L’ is the viscosity of low viscosity index standard oil (Gulf oil having

VI=0 ) at 100ºf

and also having the same viscosity of experimental oil at 210ºf. And ‘H’ viscosity of high

index standard oil (Pennsylvanian oil having VI=100) at 100ºf and also having the same

viscosity of experimental oil at 210ºf.

Viscosity curves:-

|

| Fig.2.(a). |

3.

Cloud-Point

and Pour Point:-

When

an oil is cooled slowly, the temperature at which an oil becomes cloudly in

appearance it is called its ‘cloud point’. The temperature at which the oil

ceases to flow or pour is called ‘pour point’. Cloud point and pour point

indicates the suitability of lubricants in cold conditions.

Determination of Cloud-point

and Pour-point:

Fig.3.(a). Cloud Point and Pour Point

It

is determined with the help of pour point apparatus as shown in fig(a). It

consists of a flat-bottomed tube for taking lubricating oil. The tube is

enclosed by a air jacket. The air-jacket is surrounded by freezing mixture

(ice+Cacl2) contained in a jar. The flat tube is half filled with

experimental oil. A thermometer is placed in the oil. The oil gets start cooling and

the temperature decrease slowly. At an interval of fall in temperature

every 1ºC,

the tube is withdrawn from the air jacket for a moment and examined and then

replaced in ice-bath immediately. The temperature, at which cloudness is noted

is recorded as the cloud-point. After this cooling is continued and the test tube

is removed from the cooling bath after every 3ºC

fall of temperature and tilted to observe the flow or pour of oil. The

temperature at which oil does not flow in the test tube, even when kept

horizontal for 5 second, is recorded as the pour point.

Significant: Cloud

point and pour point tells us a minimum temp at which oil can be used as a

lubricant.

4.

Flash

and Fire point:-

- Flash point: It is the lowest temperature of lubricant at which the lubricant gives enough vapours which burn for a moment, when a flame is brought near it.

- Fire Point: It is the lowest temperature of lubricant at which the lubricant gives enough vapours which burn continuously for at east five second when a small flame is brought near to is.

Significance: Flash

and fire point tells us the maximum temperature at which a lubricant can be

used.

Determination of Flash and

Fire point: The Flash and fire point is determined by penskey-marten’s apparatus as shown in fig.4.(a).

Fig.4.(a). Penskey-Marten's flash point apparatus

First

of all clean and dry all the parts of the apparatus and experimental

lubricating oil is filled up and the mark in the oil cup. The apparatus is

heated with constant stirring at the rate of about 1-2 revolutions per second.

The heating of oil cup is adjusted in such a way that the temperature of the

oil rises at the rate of about 5ºc

per minute. At every 1ºc

rise in temperature test flame is introduced for the moment with the help of a

shutter. The temperature at which a distinct

flash appears inside the up is recorded as the flash point of

lubricating oil. The heating is continued further and the test flame introduced

as before. The temperature at which the experimental lubricating oil catches

fire at least 5 seconds is recorded as its fire-point.

5.

Aniline

Point:-

It

is defined as the minimum temp. at which the lubricating oil is just miscible

with equal volume of aniline.

Significance: Aniline

point of any lubricant is a measure of aromatic content.

Determination of Aniline

Point:

Fig.5.(a). Aniline point apparatus

The whole apparatus may be

represented as in fig. The apparatus is cleaned and dried at 100-110ºc . An equal volume of pure

and dried aniline and dried oil sample have been taken in the test tube. This

test tube is fitted with electrically operated glass rod stirrer and a

thermometer . The test tube is inserted into an outer air-jacket made of heat

resistance glass. The aniline and oil sample mixture is stirred to get a

homogeneous solution . For the sometimes we use hot bath and stirring is

continued. The jacket is then withdrawn from the hot bath and the temperature

is allowed to fall at a rate below 1ºc

per minutes. For this purpose we may use cold bath. The temperature, at which

the two phases just separate out, is reported as the aniline point of the

sample.

Comments

Post a Comment